Bendywood® handrails can be bent up to a radius of 20 times the profile's cross section. A 40 mm round profile up to a radius of 800 mm, for instance, and a 50 mm profile up to a radius of 1.000 mm.

In order to be able to bend up to these limits a wood moisture content of about 12% is indispensable.

See part 2. How to bend and moisten Bendywood®.

Bendywood® handrails are delivered with a wood moisture level of approx. 12%.

The handrails should only be unpacked just before you start bending.

ATTENTION:

Bendywood® will slightly open up when taken off the mould. Therefore, in order to obtain the requested final radius, Bendywood® needs to be “overbent”, i.e. the radius needs to be kept proportionally smaller. Also see on our website under “Spring-back after being taken from the mould”.

Bendywood® bending handrails are:

- in solid hardwood

- in full sizes / not in multiple layers

- already machined, ready for bending

Our stock product range contains:

BENDING JUST BY HAND:

a. Bending an ascending handrail around a flat mould:

this is the easiest and best solution for spiral staircases!

The handrails with normal joints ![]() are also well suited for this

are also well suited for this

See video for a round handrail:

See video for a round handrail with flat bottom side:

PARTICULARLY IMPORTANT:

1. Always bend around a mould - as shown in the videos

2. Position the matching bend mould / chunks for pressing exactly opposite to the joint

3. Ascending handrails should be pre-bent around a flat mould. Only after approx. 24 hours the 3D bending can be carried out at the banister.

The following video shows how such a handrail is installed upwards:

The flat pre-bending has the following advantages:

- The transport costs are significantly lower than the costs for shipping long straight sections.

- It is possible to perform the upwards bending later, when mounting the bending handrail.

- It is also possible to combine normal wood with Bendywood®.

- Also lengths up to 13 m are feasible, as special production.

- Handrails with groove/plow are also possible.

b. Bending an ascending handrail around an ascending mould / assembly support:

If it is not possible to pre-bend around a flat mould, you can build a mould as shown in the pictures below.

BENDING BY USING A RING ROLLING BENDING MACHINE:

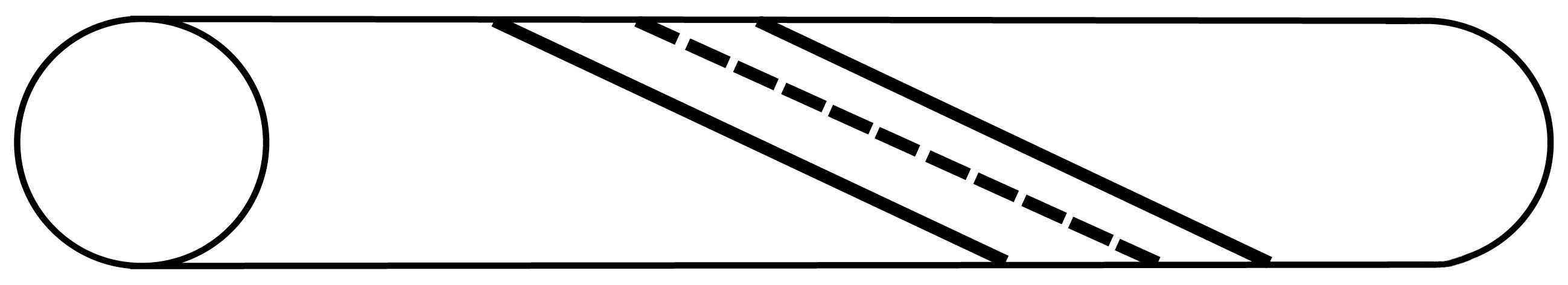

- Solely the bending handrails with diagonal joints

can be pre-bent with a ring rolling bending machine (up to a radius of 1 : 30), as only diagonal joints can endure the mechanical stress of a bending machine. A handrail with a diameter of 40 mm, for instance, can be bent up to a radius of 1.200 mm. The final bending - if necessary - up to a radius of 1 : 20 should be carried out by hand around a mould or on the banister. See the following video to this:

can be pre-bent with a ring rolling bending machine (up to a radius of 1 : 30), as only diagonal joints can endure the mechanical stress of a bending machine. A handrail with a diameter of 40 mm, for instance, can be bent up to a radius of 1.200 mm. The final bending - if necessary - up to a radius of 1 : 20 should be carried out by hand around a mould or on the banister. See the following video to this:

- Tighten the bending radius progressively, letting the handrail run through the rollers of the bending machine not more than 3 times. Bear in mind that the ring rolling bending machine also rolls the wood and rolled Bendywood® will reach its limit of flexibility more quickly. Consequently, a 40 mm thick handrail, for instance, can only be bent up to a radius of 1.200 mm by machine, then you should continue by hand.

- The bending handrails with normal joints

CANNOT be bent with a ring rolling bending machine.

CANNOT be bent with a ring rolling bending machine.

HOW TO BEND NON-ROUND HANDRAILS UPWARDS ?

All handrails turn on their own axis when being bent upwards. This torsion is not visible in case of a round handrail, as a round profile always looks the same when turned. In case of other profiles or round profiles with a groove/plow it is necessary to compensate for torsion, so that the lower part of the handrail remains below.

It is best to proceed as follows: (in one operation cycle)

First of all bend the handrail on a flat mould. Then clamp it onto the banister (which ideally has a flat steel strip or similar) starting from above. The "turning" should be carried out using a long-arm clamp, which needs to be clamped onto the handrail at a distance of 1,5 m in order to have sufficient leverage.

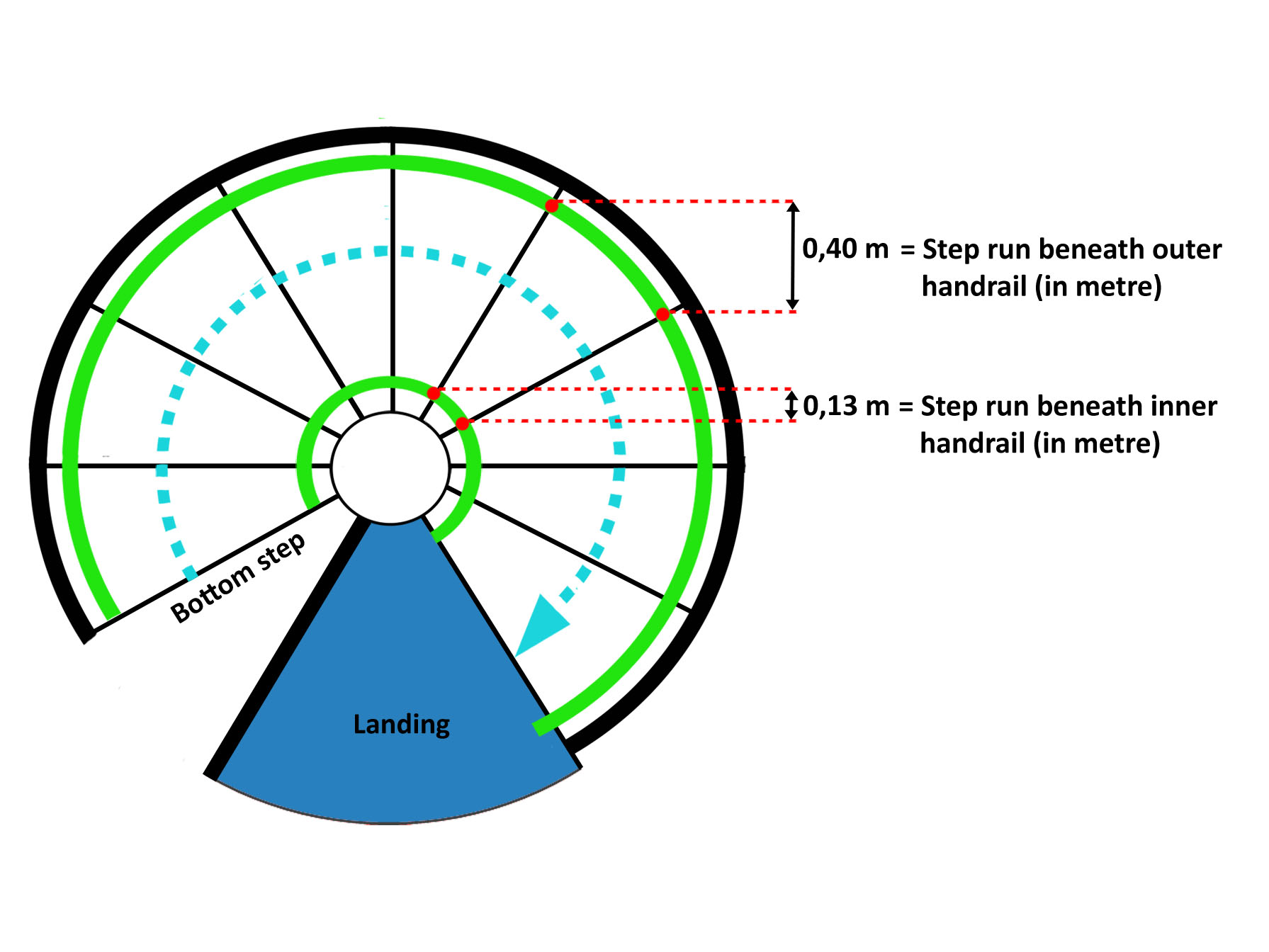

FORMULA FOR CALCULATING THE LENGTH OF A SPIRAL STAIRCASE HANDRAIL:

EXAMPLE:

Assuming:

- 18 steps

- Step rise: 17 cm

- Step run beneath inner handrail: 13 cm

- Step run beneath outer handrail: 40 cm